Charcoal Group

Investing in Quality Control

Quality control is job one in restaurants, but what about quality controls? When the Charcoal Group of Restaurants reviewed its lighting and temperature control system, they found that manually controlled dimmers, timers, and thermostats were effective when checked, adjusted regularly and desired setpoints were communicated effectively throughout the management team. But, as the number of restaurants and supervisors increased, and new staff came and went, it became more difficult to consistently maintain the corporate vision of desired lighting levels throughout all hours of the day. Due to the complicated programming, thermostats were often found displaying the wrong time, following an incorrect schedule or constantly being manually adjusted to respond to customer temperature complaints, often resulting in thermostats being put on HOLD indefinitely. Outdoor lighting timers needed to be manually adjusted throughout the seasons and failure to reset them after power outages resulted in signage being dark.

The Charcoal Group needed a system that would relieve managers of these complications without adding any new frustrations, while creating a consistently better customer environment and saving money. More than just replacing the restaurant control devices like dimmers, timers and thermostats, the Charcoal Group set out to take restaurant control to the next level. The devices needed to communicate directly with a central control system for scheduling and correct time. The system would need to be secure and easily retrofitted into existing locations while being impervious to internet disruption or reliant on technology that may someday be no longer supported by its manufacturer. Quick and easy manual override of any device was also important to maintain control comfortably within the manager’s grasp.

RecessD responded and, after rigorous testing, seamlessly integrated their control system throughout Charcoal Group’s Burlington Beertown location. Although it can be connected to the internet for head office functions, the control system operates within the restaurant as an independent local network, accessible from any phone, tablet or laptop. Managers quickly became proficient, easily making adjustments within their level of access. Manual adjustments are still possible without disruption to the underlying lighting/temperature schedules. With lighting and temperature under control, The Charcoal Group wanted to expand its efficiencies further. Much further.

RecessD identified and addressed additional economic and operational opportunities. Sensors were installed in food and beer fridges, recording temperatures every 3 minutes. Food warming lights in the pickup area were given a schedule. The RecessD Demand Control System was installed and managed by the RecessD scheduler. Multiple OFF events prevent night cleaners from running the kitchen exhaust systems all night and the exhaust/makeup air units speed up and slow down as required during the operating day. Dishwasher, bathroom, and prep hood exhaust fans were each given an operating schedule. Control of A/C rooftop dampers were integrated by RecessD so fresh air dampers close at night. Management of 25 zones of lighting, 35 sensors, 4 thermostats, multiple timers, 4 dampers, Demand Control and other devices were taken over by RecessD, making over 500 automatic adjustments per day, with no manager oversight required.

The Charcoal Group needed a system that would relieve managers of these complications without adding any new frustrations, while creating a consistently better customer environment and saving money. More than just replacing the restaurant control devices like dimmers, timers and thermostats, the Charcoal Group set out to take restaurant control to the next level. The devices needed to communicate directly with a central control system for scheduling and correct time. The system would need to be secure and easily retrofitted into existing locations while being impervious to internet disruption or reliant on technology that may someday be no longer supported by its manufacturer. Quick and easy manual override of any device was also important to maintain control comfortably within the manager’s grasp.

RecessD responded and, after rigorous testing, seamlessly integrated their control system throughout Charcoal Group’s Burlington Beertown location. Although it can be connected to the internet for head office functions, the control system operates within the restaurant as an independent local network, accessible from any phone, tablet or laptop. Managers quickly became proficient, easily making adjustments within their level of access. Manual adjustments are still possible without disruption to the underlying lighting/temperature schedules. With lighting and temperature under control, The Charcoal Group wanted to expand its efficiencies further. Much further.

RecessD identified and addressed additional economic and operational opportunities. Sensors were installed in food and beer fridges, recording temperatures every 3 minutes. Food warming lights in the pickup area were given a schedule. The RecessD Demand Control System was installed and managed by the RecessD scheduler. Multiple OFF events prevent night cleaners from running the kitchen exhaust systems all night and the exhaust/makeup air units speed up and slow down as required during the operating day. Dishwasher, bathroom, and prep hood exhaust fans were each given an operating schedule. Control of A/C rooftop dampers were integrated by RecessD so fresh air dampers close at night. Management of 25 zones of lighting, 35 sensors, 4 thermostats, multiple timers, 4 dampers, Demand Control and other devices were taken over by RecessD, making over 500 automatic adjustments per day, with no manager oversight required.

Accomplishments

RecessD has made a real difference in the consistency and efficiency of the restaurants. Lighting adjusts with sunset times throughout the year, signage is systematically illuminated at appropriate times, fridge temperature charts, over any historic period, provide management and food-safety inspectors with exact data. Exhaust fans run only when required. Thermostats are set correctly always keeping restaurants both comfortable and efficient. SCS integrates data on an ongoing basis to detect inconsistencies immediately allowing it to proactively report potential problems within mechanical systems.

Savings

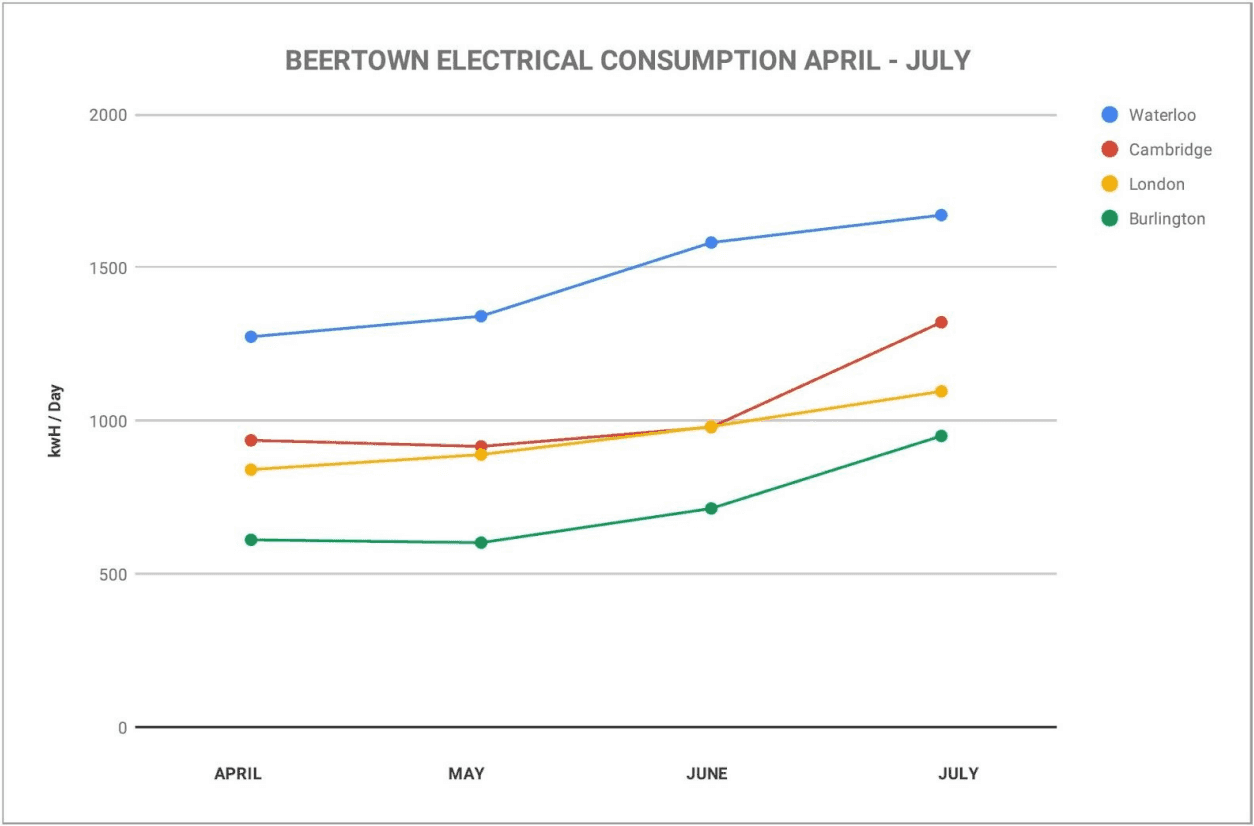

Electrical consumption is down on average 250 kwh per day (28% and $1200/mth) compared to previous years. The Burlington location is one of Charcoal’s biggest and busiest locations, yet realizes the lowest electrical bills (see chart). Reduced repairs and maintenance through efficient operation of equipment and HVAC monitoring is an added bonus. A modest decline in gas consumption has also been observed.

Payback on the full cost of the entire RecessD system has been achieved in less than 12 months.

Replication

RecessD is now operating in two additional Charcoal Group locations, is included on all upcoming new projects, and is being retrofitted into all existing locations.

Jody Palubiski, operating partner of the Charcoal Group says,

Jody Palubiski, operating partner of the Charcoal Group says,

“A new level of quality control has finally arrived in our restaurants”.